Scientists collaborating with designers to transform materials of the future

30 July 2021 | Read time: 5 minutes

Imagine clothes that could change to suit your mood, or a piece of furniture which changes to fit the environment? Or maybe a wheelchair which adapts to reduce pain.

These were some of the ideas discussed at an industry day run by SfTI’s Additive manufacturing and 3D or 4D printing of bio-composites Spearhead research project.

The industry day was just one way the Spearhead builds connections between researchers and those outside the lab. Attendees included designers, material scientists, fashion entrepreneurs, PhD students, agricultural business representatives and architects. The discussions on the day demonstrated the limitless possibilities that result from combining design thinking and industry knowledge with cutting edge research.

The Spearhead’s research focuses on bio-based responsive materials that initiate change. This means they’re creating materials that actually morph and change guided by external factors. This adds another dimension to the design process and transforms 3D printed products into 4D.

Spearhead co-leader Florian Graichen explains how, although the ground breaking materials are exciting in themselves, it’s the collaborative relationships between designers and scientists that support the realisation of new technologies and therefore have the real impact:

“Connecting designers with early stage researchers ensures human focussed design thinking is part of the earliest stage of the research. For the scientists, this guides the research toward real world potential applications. And for designers, who are used to being limited by materials which have attributes that are constant, they can see the potential of materials that are not static - materials that can change. This affects how they conceptualise their designs."

"We’re dealing with natural materials that are smart and can transform with environmental triggers. With designers alongside our scientists, they can see the possibilities are limitless. In fact it is the designer's imagination that is the limit,” he said.

A wound dressing that addresses the wound

SfTI’s Spearhead collaboration with Te Herenga Waka - Victoria University of Wellington School of Design Innovation has been key to bringing design thinking to early stage research. This relationship has involved design students working alongside materials scientists at the PhD level and bringing the knowledge of each other’s perspective to the work. One award winning outcome of this relationship has been design student Yejun Fu’s concept for an adaptive wrist splint for progressive rehabilitation. Yejun’s design won the newcomer prize at the Purmundas Challenge 2020.

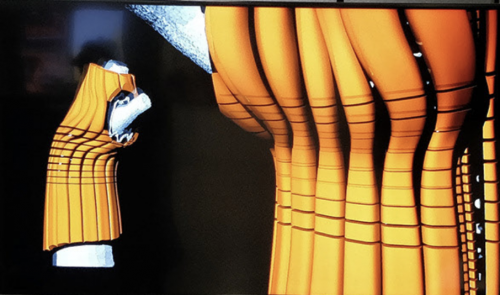

Yejun Fu worked alongside the materials scientists to determine the required functionality of the splint to best support healing and rehabilitation. Creating this responsive product involved a multi staged approach: Firstly, testing the new experimental polymers being developed within the Spearhead research to configure a printable shape-shifting layer of the splint that adapts to changes in the wrist during the healing process. Secondly, integrating these experiments into 3D models for an adaptive splint, comprising three layers, that responds to the requirements of progressive rehabilitation.