Precision farming technologies for aquaculture

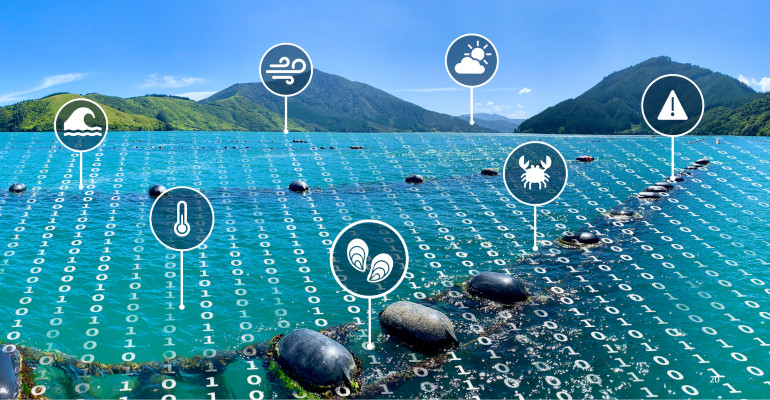

This Spearhead project is developing underwater sensors and data communication tools, alongside data analytics to let farmers monitor their ocean farms from their home base.

Team

Spearhead Leader, Dr Chris Cornelisen – Cawthron Institute, Coastal and Freshwater Group Manager

Heni Unwin – Cawthron Institute, Coastal and Freshwater Researcher and Vision Mātauranga Lead

The project involves additional researchers from Cawthron, GNS Science, Product Accelerator, the Universities of: Auckland, Canterbury, Massey, and the Victoria University of Wellington.

Aquaculture is one of New Zealand’s fastest growing export industries, with our Greenshell ™ Mussels, King Salmon and Pacific Oysters in hot demand all over the world. Innovation is needed to enable the industry to reach and exceed its ambitious Government target of $3 billion in revenue by 2035.

Watch an update from the Spearhead team.The Spearhead project is developing sensors and data communication tools alongside data analytics that will enable aquaculture farmers to monitor their ocean farms remotely on their mobile phones or home computers. A key aim is to produce cost-effective sensors that can be easily deployed and maintained in large numbers across multiple farms. The technologies being created are practical in their design and draw on the team’s many years of experience deploying ocean instrumentation. The integrated technologies will ultimately generate the right types and amounts of data needed to remotely manage farms.

Snapshot

Our thriving aquaculture industry is looking to new ‘precision’ technology to allow the growth and efficiencies that will take it to the next level.

The team has refined and tested sensor and communication prototypes that are undergoing early stage commercialisation testing in marine farms across Te Tau Ihu (Top of the South Island).

By mid-late 2022, the team aims to have sensors deployed at multiple farms across Aotearoa, and deliver the data remotely through user-friendly ‘dashboards’.

Alongside the Spearhead, the project team is working closely with industry representatives to establish a collaborative forum aimed at accelerating the transfer and global commercialisation of ocean data technologies.

Making the most of our oceans’ bounty

Currently, marine shellfish farmers in NZ need to manage their farm crops and structures by frequently going out on boats and pulling up lines to check their crops. Water quality is usually assessed manually, by lowering an instrument with sensors and/or taking water samples for analysis in the laboratory. This method of farming requires vessels and staff to be out on the water for large amounts of time. This not only poses a large cost for an aquaculture operation but is also weather-dependent, especially for larger farms in exposed waters.

Marine farmers are hungry for useful data about their farm structures, crops, and the quality of growing waters. Having real-time data made easily accessible via a farmers laptop or mobile phone is incredibly beneficial for both day-to-day management and longer-term monitoring of aquatic health and environmental trends. There are existing sensor technologies for remotely collecting ocean data, however, they are not conducive to aquaculture applications and are geared toward ocean observing oceanographic research and modelling. Spearhead researchers work closely with aquaculture farmers to ensure technologies are fit-for-purpose by continually trialing equipment on marine farms.

Innovating with precision aquaculture

Precision agriculture has now become a common catchphrase. In precision agriculture, farmers use drones to estimate soil moisture from the air, automate their irrigation systems, use GPS-equipped harvesters, or even track and move their stock.

Precision aquaculture envisages marine farmers using technology and data-driven decision-making to achieve more efficient management of aquaculture farms in the same way as their land-based counterparts.

Together with scientists from across New Zealand universities and industry participants, the team is developing sensor and communication technologies, and the data analytics required to convert large amounts of data into useful tools for farmers. The aim of this research is to support aquaculture in Aotearoa to transform into a high-tech, knowledge-based industry.

Focus on tech

The scalable technologies developed by the project allow for remote monitoring of farm structures (above and beneath the water), stock health and condition as well as water quality and environmental conditions. These remote monitoring technologies will be of use to all marine farmers, but especially those working in isolated areas and/or operating larger farms in challenging offshore environments. The project is developing a user-friendly dashboard that enables farmers to ‘see’ their farm and the conditions of their crops and surrounding growing waters from a tablet or smartphone. The research on new sensor technologies is cutting edge. For example, project researchers from the University of Auckland are developing photonic sensing techniques to measure mussel food (plankton) and other parameters of interest in the water.

The project has multiple pieces of technology in development that combined will generate the data required to enable precision aquaculture. The data collected from these new technologies will be integrated and compiled to drive visualisation tools for marine farmers. Tools in production include a digital dashboard providing farmers with real-time information on their farms and crops, as well as links to forecasts of interest, such as where and when the next settlement of mussel spat is likely to happen, or the risk of contamination due to recent rainfall and runoff from land.

A NEST for sensors

The first challenge was to design a power and communications platform for deploying sensors easily on marine farms. Typically sensors are deployed on stand-alone moorings or ‘data buoys’ that require additional expense and consenting for their placement. For long-line shellfish farming, the spearhead invented a NEST (Novel Environmental Sensor Technology) float, which is integrated into the farm itself and makes for easy deployment of power and communication inserts or metal frames for cameras and other sensors

Sensor technologies in development

IoT temperature string: A heavy-duty cable with multiple temperature sensors hangs below the NEST float and collects water temperature across depths where crops are farmed. Data is delivered remotely to land via an Internet of Things (IoT) network such as Spark’s Cat-M1 network. Power and communications capability are delivered to the sensors along the string via the power and communications insert

Imaging intelligence: Managing flotation on mussel farms is a major task and requires frequent visits by boat. The team is trialing cameras mounted above the water that report back the status of mussel floats to farmers. Images are analysed using AI on a computer processor located on the NEST float. This on-site data processing is termed edge computing and allows information captured by the camera, such as the number of mussel floats it sees, to be reported over the IoT network without the need to send data-rich images or video. The data will allow farmers to check the status of their floats and lines, along with information on sea conditions, wildlife and vessel interactions remotely from land.

IoT Smart float: New Zealand has in excess of 600 Greenshell mussel farms around the country, all with numerous longlines that in turn support thousands of meters of crop line amassed with mussels. Keeping the industry afloat, literally, are buoys that hold the longlines up. Professor Johan Potgieter’s team at Massey University and John Futter (GNS) have developed a sensor that will transform standard floats into data collection devices. The sensor is placed within the float and measures its location and how much the float is sitting in the water (depth). The data is sent back to the office or lab via the IoT network. The second iteration is successfully deployed alongside the stationary camera on a mussel farm in the Marlborough Sounds. Read more

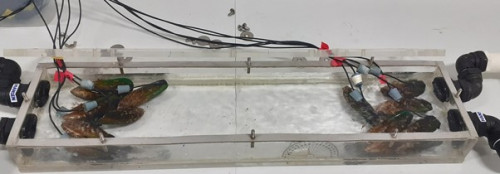

‘Mussel mood’ sensor: Hall-effect sensors (based on detections of a generated magnetic field) attached to mussel shells are being used to measure the frequency and extent of opening and closing of mussels (gaping). The prototype will include multiple mussels with sensors wired to the surface using the same technology as the IoT temperature string. Laboratory trials of the sensors and analyses of mussel gaping data are being analysed to determine indicators of feeding, growth, stress and mortality. Mussels have long been used as sentinels for gauging water quality. Plans are for the mussel sensors to be integrated into a smart ‘kete’ for applications by iwi, such as monitoring of customary harvest areas or rohe moana

Spearhead Vision Mātauranga Lead, Heni Unwin, has developed the 'mussel mood' sensor by interweaving Te Ao Māori with western science. The research draws upon mātauranga Māori to enhance understanding of Kūtai mussel health. Find out more about her work and how the mussel mood sensors enable the team to gather information from the mussels themselves that can act as sentinel species telling you about the environment and the ocean.

Photonic sensors: Team members from University of Auckland are developing Raman spectroscopy techniques to assess food quality and the presence of contaminants/toxins in the marine environment. They are calibrating and validating the ability of the technology for describing the types of phytoplankton.

An ‘autonomous’ remotely operated vehicle (ROV): Using the open-source BlueRobotics hardware platform (known internationally as BlueROV), the team has been developing custom electronics and firmware to expand its applications and ease of use for aquaculture farmers. Stereo cameras mounted on the front capture 3D images of underwater objects and environments, while the eight thrusters enable full positional and rotational control. Pilot training applications will be provided as part of the ROV software package.

A BlueROV in action using its stereoscopic vision and AI programming to autonomously navigate up and down a mussel line. Courtesy of University of CanterburyThe ultimate aim is to provide farmers with a cost-effective solution for rapidly surveying their farm structures and crops. Using stereoscopic vision and an Artificial Intelligence (AI)I technique called machine learning, the augmented ROV can be placed in the water by farmers to automatically ‘scan’ farm structures, assess crop condition, or even detect pest species.

The next task is to work out how to transmit data wirelessly from the BlueROV to the surface, which would avoid any need for cables that can become tangled in farm structures. The team is trialling blue light spectrum wavelength technology to send information through water. In the laboratory, they’ve been able to transmit 4K video wirelessly for several metres through murky waters.

Technology to monitor New Zealand’s coastal waters

While helping Aotearoa New Zealand’s aquaculture industry grow, there’s scope for the technology to help manage dredging activities, shipping and biosecurity threats in ports and harbours and collect data useful in tracking the state of our coastal waters. The team ultimately want their advanced sensors to join the export market as their precision aquaculture innovations head offshore to aid the accelerating growth of aquaculture worldwide.

Precision Aquaculture in the media

Engineering New Zealand: 'Green Growth in a blue setting'

Read an article in Engineering New Zealand about the work of the Precision Aquaculture Spearhead project published in June 2022.

Project background

This Mission-led Spearhead Project commenced in 2017, ending in June 2022 and has received a total of $5M funding. Find out how we develop our Mission-led projects.